A Plant-Based Diet That Packs a Protein Punch

A Plant-Based Diet That Packs a Protein Punch

Plant-based protein food is all the rage now, but consumers may not be getting all the proteins they need. Microalgae proteins, sourced from fermented food waste, may be the solution – and Singapore could be a major exporter in the future.

Microalgae protein could potentially power a circular economy as it relies on food waste for production.

It looks like salmon and tastes like salmon. Except, it’s not salmon. To the uninitiated, the dish offered by Sophie’s Kitchen could pass off as the real deal.

Made from plants, vegan salmon is one of the many offerings at the California plant-based seafood retailer. Along with brands like Impossible Foods and Beyond Meat, mock seafood has been a mainstay in the market for a while.

However, it is known to lack the full nutritional profile of real seafood as its main ingredients – pea and konjac – contain different nutrition content and less protein than most seafood.

Enter Mr Eugene Wang, Sophie’s Kitchen’s co-founder. The 51-year-old, a pioneer in the plant-based seafood industry, recently discovered how to replicate protein levels found in seafood using microalgae, a sea plant, instead of the resource-intensive land-based protein sources.

The mock seafood experiment

In 2017, a win at SLINGSHOT@SWITCH, a start-up competition by Startup SG, gave him the opportunity to develop his idea.

Through consultations with scientists from Nanyang Technological University, National University of Singapore and the Agency for Science, Technology and Research (A*STAR), he discovered the nutritional difference between two types of sea plants – microalgae and macroalgae.

Macroalgae, such as kelp and seaweed, are low in protein and susceptible to pollution. Microalgae, in comparison, yield higher protein and can be grown in a controlled environment, including being fermented from food waste. Certain species can even contain more protein than meat.

Databases provided by overseas university partners allowed him to identify a strain of microalgae – out of more than 800 documented – that could be easily fermented in the dark. There are an estimated 30,000 to one million microalgae species.

With fermentation, the space needed to farm is greatly reduced as we can go vertical, and the process is carbon-neutral because we set the growth conditions.

Eugene Wang, Founder of Sophie's Kitchen

Currently, the strain of microalgae he uses has a natural “fishy” taste, which is closer in taste to seafood. But he plans to explore more strains to ferment once the initial batch takes off, to achieve a more neutral taste that can be used for other types of food such as meat and tofu.

Singapore – microalgae protein powerhouse

This year, the project was given a boost after Mr Wang and his team won S$1 million at The Liveability Challenge (TLC) 2019 organised by Temasek Foundation in June.

Launched in 2018, The Liveability Challenge is an international platform where sustainable ideas and innovations are showcased, allowing winners to secure funding and opportunities to further develop their solutions.

“Singapore is a place built up for innovators in terms of entrepreneurial spirit, because you get a lot more attention here than in a crowded place like Silicon Valley,” he said. “So in many ways, I feel like I owe Singapore a token of appreciation.”

The country’s proximity to bigger overseas markets and influx of global talents gives him confidence that it can become a microalgae protein powerhouse.

“There’s not a lot of alternative protein out of the region, and even if there are, it’s mostly supplied locally,” he noted. “I’m hoping to be the first one to sell microalgae as an ingredient globally with an Asian management team.”

Operations shifted from his family-owned vegetarian production facility in Taiwan to Singapore starting from August 2019. A pilot run of 250 litres of microalgae will be fermented in tanks located at A*STAR’s Biotransformation Innovation Platform. Once successful, the volume will be progressively increased to 60 tonnes.

“With our technology, Singapore has the potential to become a protein exporting powerhouse contending with major protein exporting countries,” he added.

Credit: Temasek

Overcoming the “yikes” factor

This is not Mr Wang’s first foray into the vegetarian market. His grandparents led the way as street vendors selling vegetarian food before his father, a food scientist, set up their family vegetarian food manufacturing plant.

His own entrepreneurial experience in plant-based food started when he created vegetarian seafood dishes for his daughter, who is allergic to seafood. Encouraged by a friend, he decided to open a business – and Sophie’s Kitchen, named after his daughter, was born.

Now, he hopes to build on the first startup’s success. He believes that microalgae protein could power a circular economy as it relies on food waste for production.

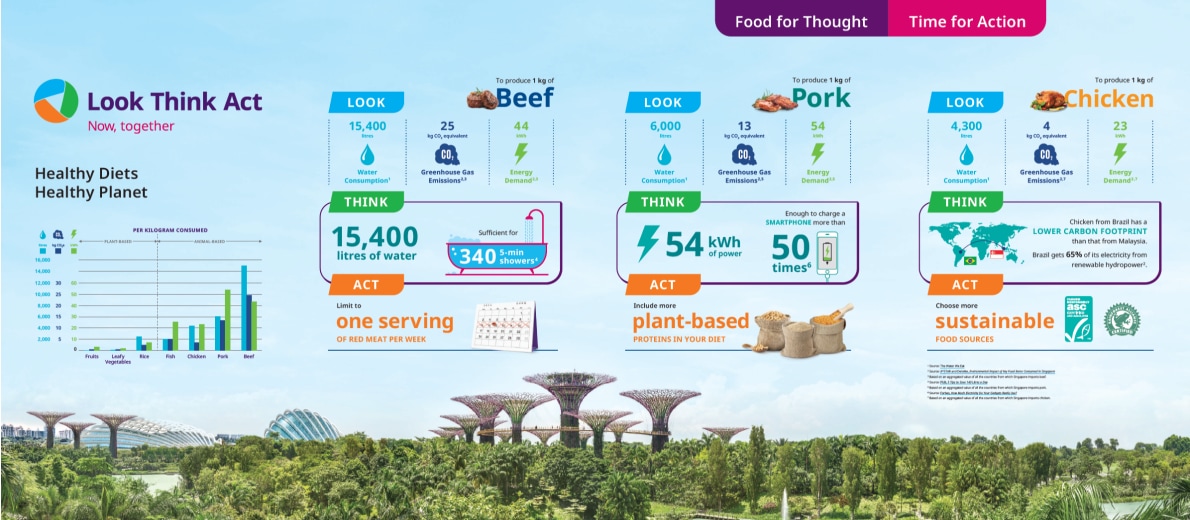

Research has also shown that people who consume less red meat and dairy have a lower carbon footprint. With the growing human population, climate change and increasing ethical concerns around animal agriculture, he hopes he can scale up his idea to be the carbon neutral protein solution the world desperately needs.

“One tonne of our plant-based proteins uses less than 0.02 hectares of land, compared to almost 141 hectares needed for one tonne of beef proteins,” Mr Wang pointed out.

However, for that vision to be realised, he has to first convince people to switch diets. Luckily, plant-based diets are becoming more and more popular as the result of protein pioneers such as Beyond Meat, Impossible Foods, and now, Sophie’s Kitchen.

“This will require capital and the right team to educate food manufacturers on how best to use our protein in their products. We expect this will be relatively easy because we will cut their food costs significantly without sacrificing nutrition.”

“Beyond Asia, when you talk about microalgae, there’s a ‘yikes’ effect, until we explain that it is just the salad of the sea. Microalgae comes with a lot of health and nutritional benefits that terrestrial leafy greens simply can’t compete with,” he added.

With nearly half the capital required to produce a commercial product now secured, he has already set his sights much further. His final frontier is space – providing astronauts with microalgae-based food in the future.

“If a suitable microalgae strain is found, it can even be grown in open space on Mars,” he quipped.