Burning Questions: A Concrete Step Towards More Sustainable Cities

Burning Questions: A Concrete Step Towards More Sustainable Cities

In brief:

- The cement sector produces almost three times more CO2 emissions than the aviation sector

- Almost half of this is released when its key ingredient, limestone, is heated in a kiln

- Materials technology company Fortera reduces emissions by recycling the CO2 emitted by limestone back into its product

Cement makes up just 10-15% of concrete, but is almost exclusively responsible for its CO2 emissions. As populations grow and urban development gathers momentum, green cement will make for more sustainable cities, while moving the needle closer to net zero.

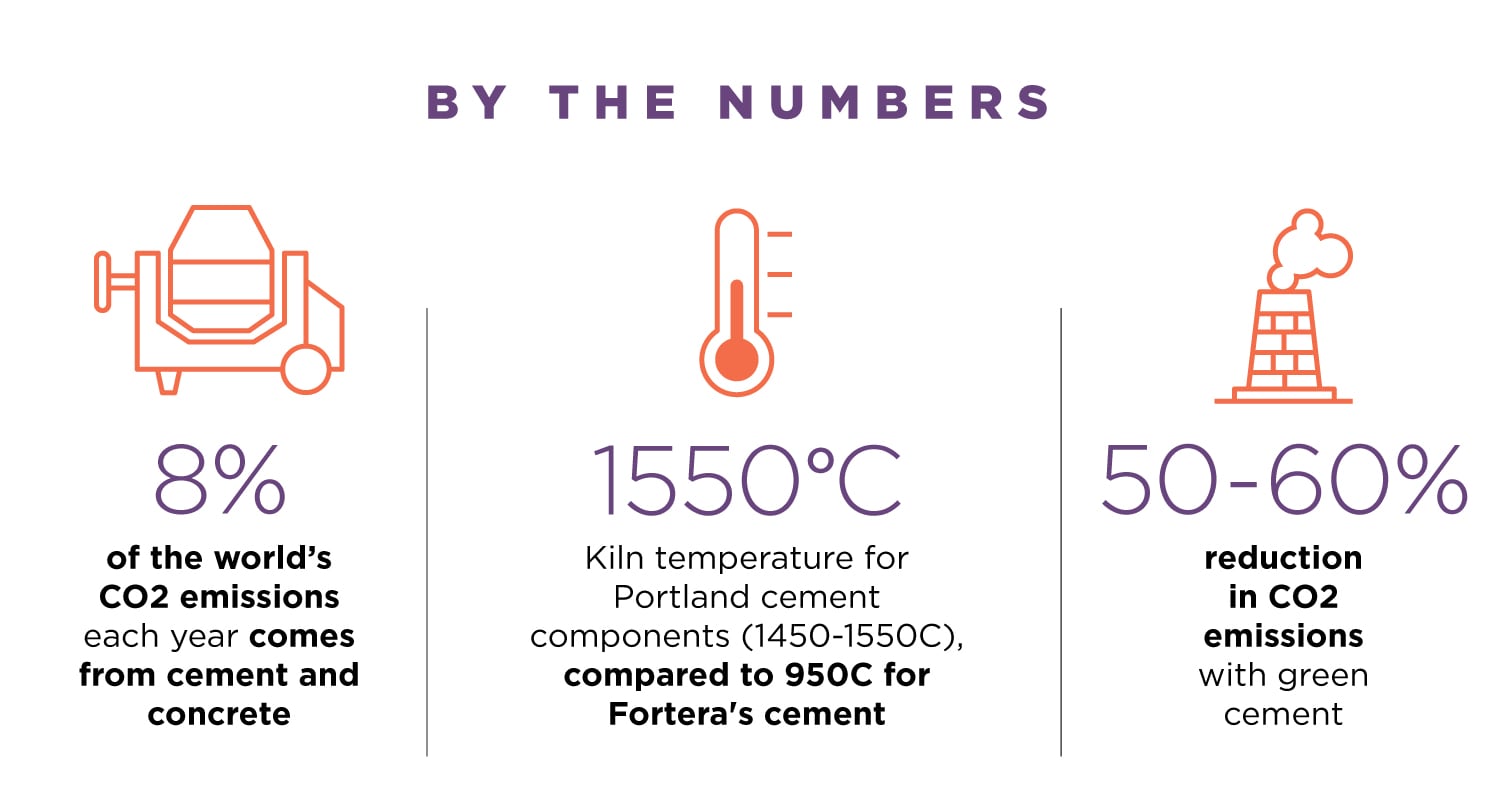

After water, concrete is the second most widely-used substance on the planet. It is also one of the world’s biggest carbon offenders, generating 8% of global CO2 emissions annually.

Almost all these emissions come from a single ingredient: cement. Making up just 10-15% of the concrete mix, cement is responsible for 95% of its emissions. The vast majority of this is generated during the production process.

Aubrey Keller, VP, Emerging Technologies Team, Temasek, and Ryan Gilliam, CEO & Co-Founder of materials technology company Fortera, answer your Burning Questions on how scaling a promising technology can bring the industry closer to net zero.

We have a limited period of time to address climate change, so we need to think not only about the solutions that are available, but how fast we can scale them and introduce them into the market so that they are actually moving the needle on reducing carbon emissions.

Aubrey Keller, VP, Emerging Technologies Team, Temasek

Why is decarbonising cement so critical?

Aubrey: Cement is one of the most commonly used construction materials globally – and one of the world’s largest carbon emitters, contributing roughly 8% to global greenhouse gas emissions. The size of the market makes it a huge problem, especially as many emerging economies still need to develop their built environments. Conversely, the benefits of decarbonising this industry will be massive.

Ryan: The staggering fact is that concrete is the second most consumed product on earth, behind water, and cement is the “glue” that holds it together. There is really no substitute that can be produced at the same volume and cost.

How can cement be made more sustainably?

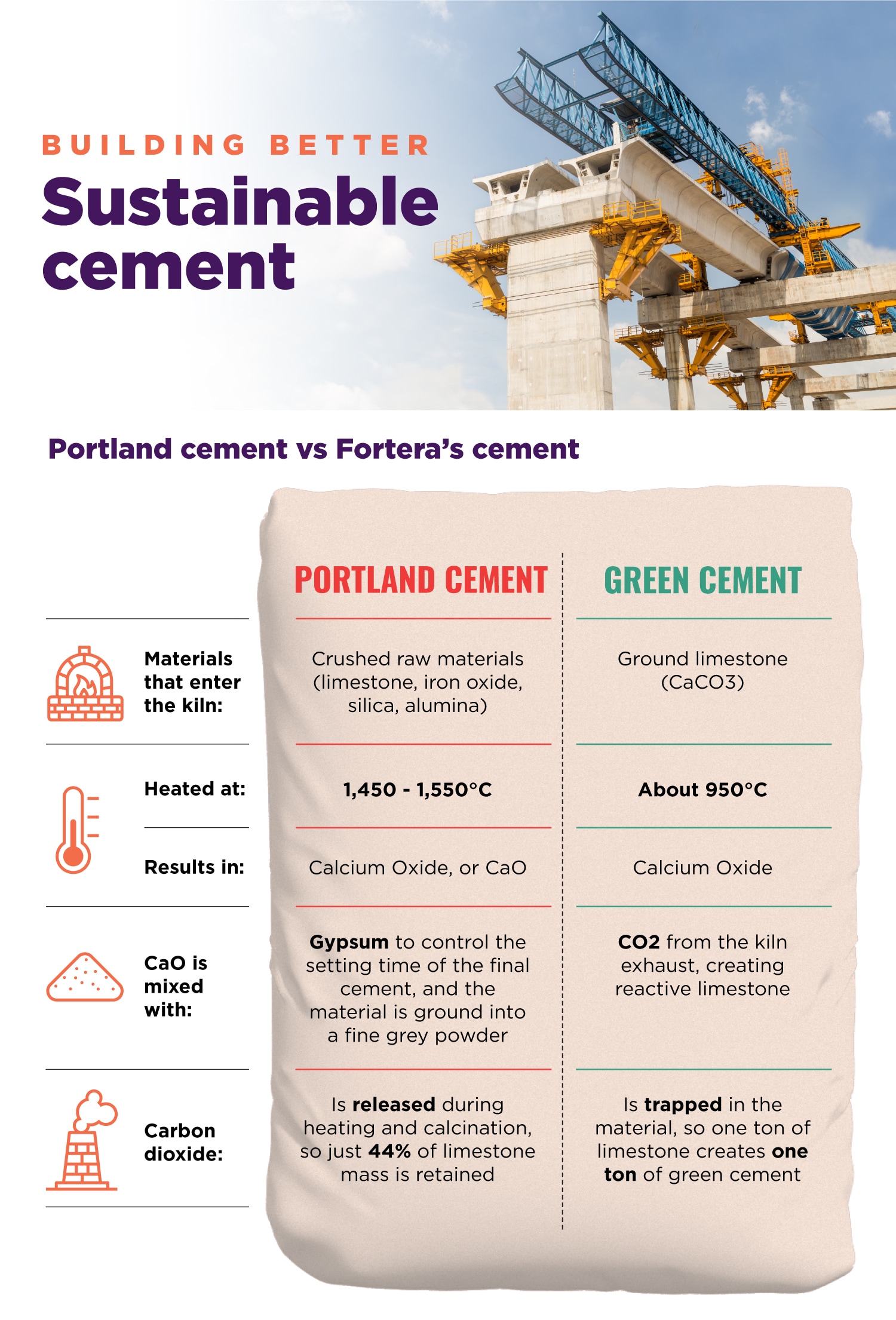

Aubrey: The production of traditional – or Portland – cement contributes to carbon emissions in two ways: from heating its raw materials to super-high temperatures in kilns fired almost exclusively with fossil fuels; and from the large amounts of carbon dioxide released by its main ingredient, limestone, when superheated. Fortera’s solution reduces carbon emissions by up to 60% by using lower temperatures, and recycling the CO2 emitted by limestone back into the cement.

What are the benefits of cement made through this process?

Ryan: In traditional – or Portland – cement, 80% of the feedstock is limestone. The challenge is that when you heat it, you lose almost half of its weight in CO2 emissions. Our proprietary process allows us recapture those emissions and turn them back into product. So for every ton of feedstock, we have a ton of sellable product, and almost 50% of that weight is captured C02. That creates both an economic advantage and an environmental benefit. We also fit within the existing ecosystem, in that we use the same infrastructure, from quarry to kiln.

Aubrey: This is a critical factor. Because we have a limited period of time to address climate change, we don’t just need to think about the technology, but how quickly it can be introduced into the market. A process that fits into the existing ecosystem, using existing supply chains and feedstocks, means producers can hit the ground running, scale up and reduce carbon emissions immediately.

What are the challenges in getting new technologies adopted by the industry?

Aubrey: There are three – can the technology be used with the existing infrastructure? Is it cost competitive? Is it scalable? We have a technology that fits, the issue now is how quickly we can scale it to drive down operating costs. The cement industry has been incredibly successful at producing high volumes at very low cost. The challenge lies in getting this technology to scale so it makes economic sense for the industry to adopt it.

Ryan: One of the main hurdles has been getting from pilot to commercial. Economies of scale matter, you need to build large plants to drive down capital and operating costs. And that's the fundamental challenge. You need funding support, but also investors who are strategically aligned with where you are trying to get to, and that can open the right doors. Temasek has been instrumental in enabling us to move forward.

What is going to drive the mass adoption of green cement?

Aubrey: If you want people to use your solution, you have to make it easy for them, and as far as possible, no different from how they are already mixing concrete and building buildings. Fortera’s material can be easily blended into the concrete mix, and there is ongoing dialogue with regulators worldwide to increase the proportion that can be blended. Secondly, it has to be cost competitive, so we go back to the idea of scaling and achieving economies of scale.

Ryan: Our goal is to have the same cost as traditional cement. From day one, we’ve also been focused on ensuring that our material meets the same strength profile, set time, and flow as traditional cement, and integrates seamlessly into concrete applications. Consumers then have the option to buy a green product with the same performance and costs. That’s going to help drive adoption.

Is net zero by 2050 realistic for this industry?

Aubrey: I think there's a lot of will to reach net zero. But does the cement industry have solutions to create a meaningful impact on an over 4 billion tonne a year addressable market? This is why we need to find solutions that are cost competitive, scalable and allow people to replace current concrete with a decarbonised solution, without a huge economic impact.

Ryan: We’ve found that cement companies are committed to a net zero future. We have had no shortage of companies willing to test our material and validate it. The next step is for large companies to be willing to be first adopters at an industrial scale. It’s a big leap, but based on the interest we have seen, I am hopeful.

At Temasek, sustainability is at the core of all that we do. We actively work with our portfolio companies to address the climate challenge, reverse loss of nature and build a more inclusive society.

Temasek is an investor in Fortera.